Laser protection clothing Laser Safety Clothing following Laser Safety Standards CE/EN 60825-1/4, IEC 60825-1/13, GB 7247.1/4/13、

PPE for yout body and your hands

LASER PROTECTIVE GLOVES

Laser Safety gloves+

Laser Protective Performance with 1064nm Laser:

material: inner special fabric with high temperature resistance of 3000'℃ + outer aramid fabric

No Penetration: tested under:

Power density: 300w/cm'

test-power = 83w,

beam diameter = 6 mm,

distance=90mm,

time of test: for 10 seconds)

black/grey colour material

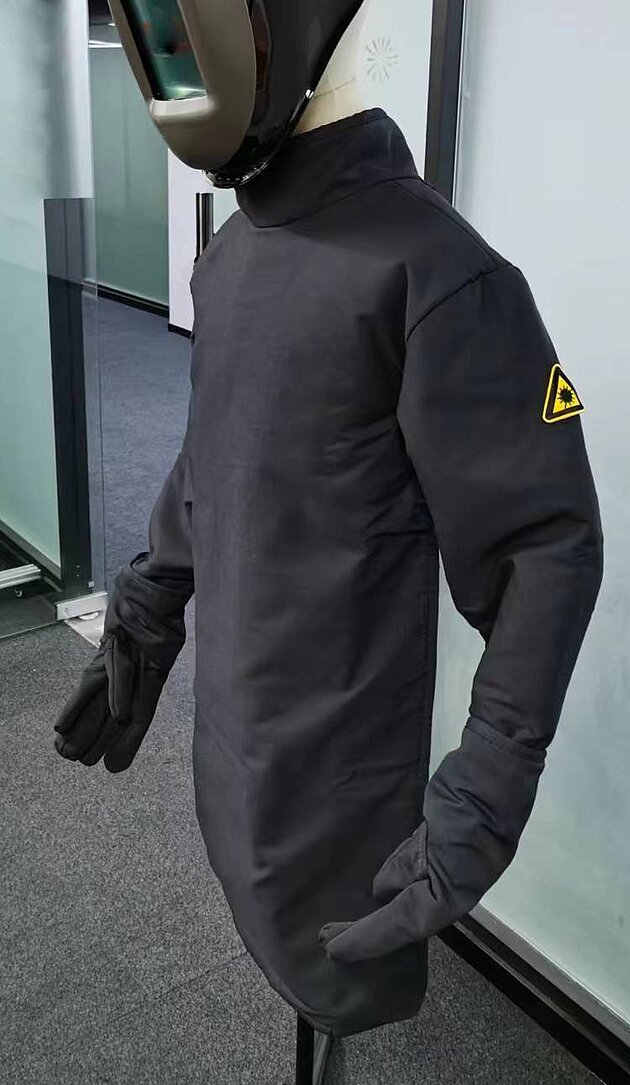

LASER PROTECTING APPRON

Certified Laser-Safe Apron

Because of the increasing application of high-power handheld laser welding systems, this kind of working protection has become more and more important. The Laser Safety Apron employs breathable technology and features certified resistance of 3.000 kW/m² against laser radiation of 1064 nm before exceeding the maximum permissible exposure skin value.

- Suitable for use according to the welding protection standard EN ISO11611

- Suitable for use according to heat and flame protection standard EN ISO 11612

- Tested following laser Standard DIN EN 12254:2012-04

is a laser protective clothing is cut and sewn with Laser Defender laser protective curtains. It is the only professional laser protective clothing . The standard product of Laser Safety World laser protective clothing is in the form of a one-piece apron, with a length of 1.2m, one size fits all, designed with adjustable elastic buckle, suitable for most body shapes. There is two series of standard photoelectric version and enhanced industrial version. The standard photoelectric version is equipped with dust-free anti-static and flame-resistant outer lining, which is suitable for optical communication, semiconductor microelectronics with low power and clean room operation and other industries. The enhanced industrial version is suitable for industrial laser processing occasions, especially for handheld laser processing operators.

Laser welding clothes composed with partialy ARAMID fibres

Carbon Fiber vs Aramid Fiber: Everything You Need to Know

Carbon fiber and aramid fiber are two popular types of high-performance fibers. These are used in various industries and are known for their excellent strength-to-weight ratio, durability, and resistance to heat and chemicals. However, despite their similarities, these fibers have distinct differences that affect their performance and application. In this article, we'll explore the differences between carbon fiber and aramid fiber and their pros and cons.

Is Aramid Fiber the Same as Carbon Fiber?

No, aramid fiber is not the same as carbon fiber. While both fibers are classified as "advanced composites," they have different chemical structures and properties.

Carbon fiber is made of thin strands of carbon atoms, which are tightly bound and oriented in a specific direction. The carbon fibers are then woven into fabrics or mats and impregnated with resin to form composite materials. It is known for its high tensile strength, stiffness, and low weight.

Aramid fiber, on the other hand, is a type of synthetic polymer that contains aromatic rings in its molecular structure. The most well-known fiber is Kevlar, which is used in bulletproof vests, helmets, and other protective gear. Aramid fiber has excellent resistance to impact, abrasion, and heat, but is less stiff and strong.

Carbon Fiber vs Kevlar

Kevlar is a brand name for a type of aramid fiber developed by DuPont in the 1960s. It is widely used in ballistic protection, such as bulletproof vests, helmets, and vehicle armor. Kevlar has a tensile strength of around 3.6 GPa (gigapascals), which is five times stronger than steel on a weight-to-weight basis.

Compared to carbon fiber, Kevlar has a lower stiffness and strength, but higher impact resistance and toughness. Kevlar is also more resistant to heat and chemicals. However, Kevlar is not as widely used in structural applications, due to its lower strength and stiffness.